It’s plain to see that electric vehicles are the future, but there’s more to making that change happen than swapping out a gas motor for a battery-powered one — especially in aircraft. H3x is a startup that aims to accelerate that future with a reimagined, completely integrated electric motor that it claims outperforms everything on the market.

The small founding team — CEO Jason Sylvestre, CTO Max Liben, and COO Eric Maciolek — met in college while participating in an electric vehicle building and racing program. After stints in the tech and automobile industry (including at Tesla), the crew came back together when they saw that the Department of Energy was offering a bounty for improved high-density electric motors.

“The problem was uniquely suited to our abilities, and passions too — we’re excited about this stuff. We care about decarbonization of the different transit sectors, and aviation is going to become a growing part of the global carbon footprint over the next few decades as electric improves ground vehicles,” said Liben. “We just kinda decided to take a leap of faith, and applied to Y Combinator.”

Electric flight isn’t so much a wild idea as one that’s in its early, awkward stages. Lightweight craft like drones can do a great deal with the batteries and motors that are available, and converted small aircraft like seaplanes are able to make short flights, but that’s about the limit with the way things are today.

The problem is primarily a simple lack of power: the energy required to propel an aircraft fast enough to generate lift grows exponentially as the size and mass of the plane increase. A handful of kilowatt-hours will serve for a drone, and a few EV-scale batteries will work for a light aircraft… but beyond that the energy required to take flight requires batteries the bulk and weight of which make flight impractical.

Of course, it doesn’t have to be like that. And there are two general avenues for improvement: better batteries or better motors. So either you can fit more energy in the same mass or use what energy you have more efficiently. Both are being pursued by many companies, but H3x claims to have made a huge leap forward in efficiency that could unlock new industries overnight. While even an improvement of 10 or 20 percent in power per kilogram (e.g. a 50-pound motor putting out 120 horsepower rather than 100) would be notable, H3x says its motor is performing at around 300 percent of the competition’s output.

Of course, it doesn’t have to be like that. And there are two general avenues for improvement: better batteries or better motors. So either you can fit more energy in the same mass or use what energy you have more efficiently. Both are being pursued by many companies, but H3x claims to have made a huge leap forward in efficiency that could unlock new industries overnight. While even an improvement of 10 or 20 percent in power per kilogram (e.g. a 50-pound motor putting out 120 horsepower rather than 100) would be notable, H3x says its motor is performing at around 300 percent of the competition’s output.

How? It’s all about integration, Liben explained. While the pieces are similar in some ways to motors and power assemblies out there now, the team basically started from scratch with the idea of maximizing efficiency and minimizing size.

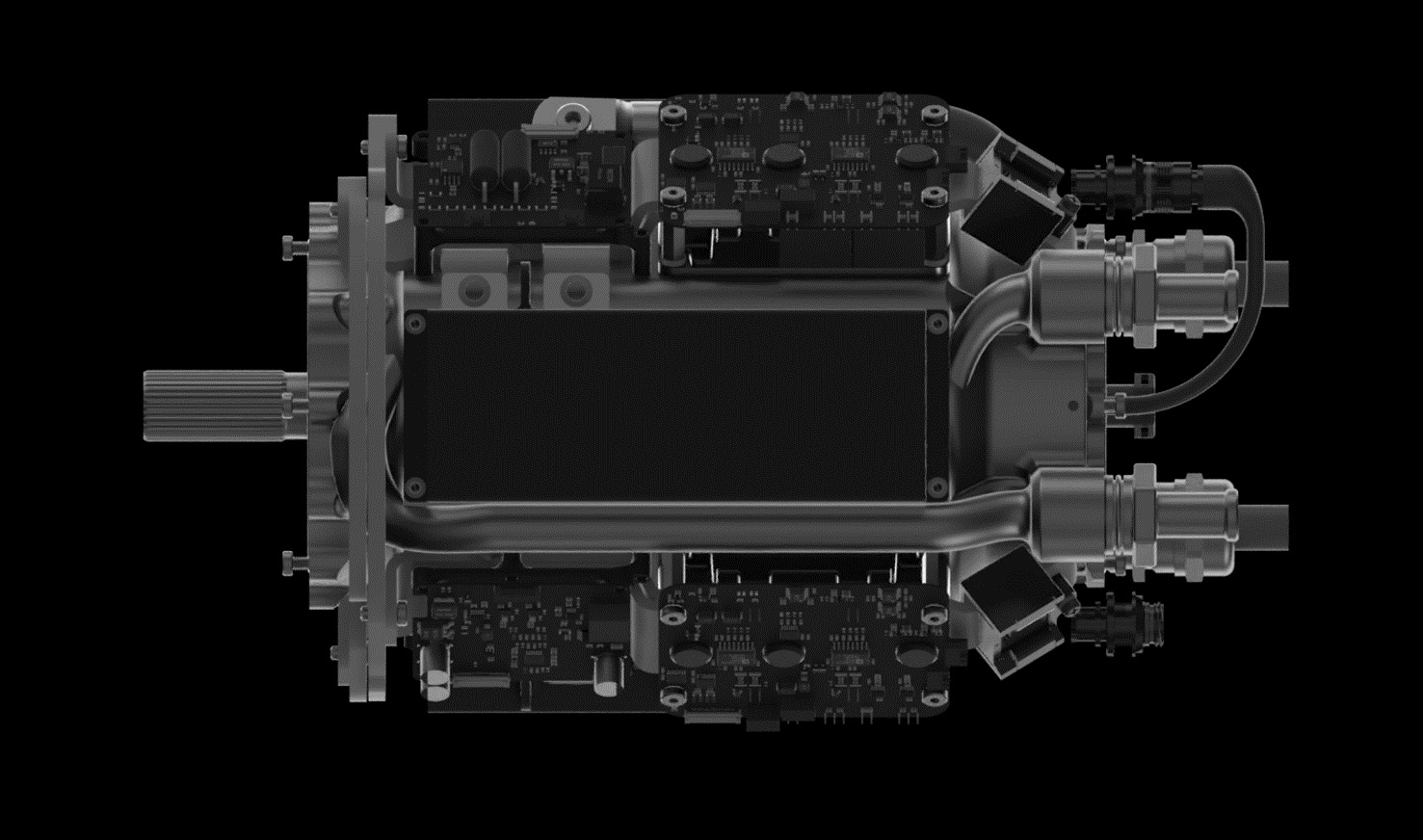

Electric motors generally have three main sections: the motor itself, a power delivery system, and a gearbox, each of which may have its own housing and be sold and mounted separately from one another. One reason why these aren’t all one big machine is temperature: the parts and coolant systems of the gearbox, for instance, might not be able to operate at the temperatures generated by the motor or the power system, or vice versa. Put them together and one may cause the other to seize up or otherwise fail. The different sections just have different requirements, which seems natural.

H3x challenges this paradigm with a novel integrated design, but Liben was careful to clarify what that means.

“We’re not just taking the inverter box and slapping it on top and calling it integrated,” he said. “All the components are all intimately connected to the same housing and motor. We’re making a truly integrated design that’s one of the first of its kind at this power level.”

And by “one of the first” he doesn’t mean that Airbus has one in some powertrains, but rather that there have been research projects along these lines — nothing intended for production.

The idea that no one else has gone this far in putting everything in the same box at scales that could be used commercially may sound suspicious to some. One would think that the existing players in aerospace would have been barking up this tree for years, but Liben said large companies are too slow to innovate and too invested in other methods, while smaller ones tend to avoid risk by improving incrementally on successful existing designs and competing among themselves. “No one is targeting the level of performance we’re looking at right now,” he said.

But it isn’t like H3x stumbled over a single advance that magically tripled the performance of electric motors.

“We’re not relying on one big tech or something — there’s no magic bullet,” Liben said. “There are a few improvements that have very significant gains, like 50 percent better than the state of the art, and lots of areas that add 10-20 percent. It’s good from the technical risk side.”

He went into considerable detail on a lot of those improvements, but the less technical-minded among our readers, if they’ve even read this far, might close the tab if I tried to recount the whole conversation. To be brief, it amounts to combining advances in materials, manufacturing, and electric components so that they act synergistically, each enabling the other to be used to best effect.

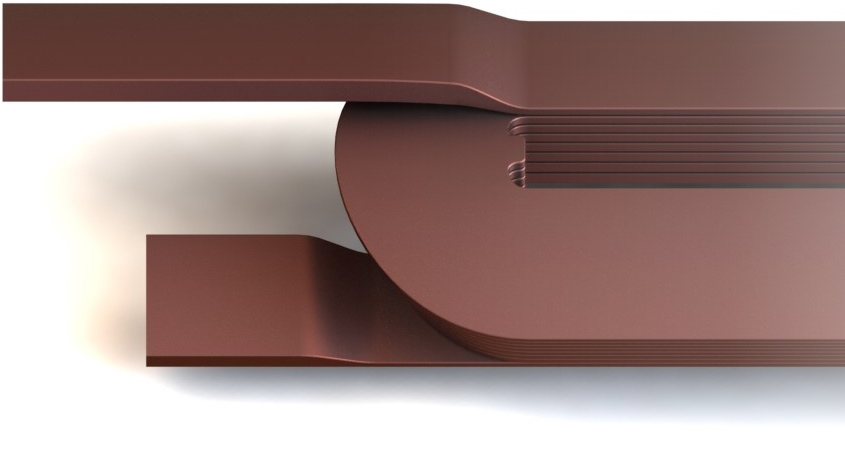

For instance, recently improved power switching hardware can be run at hotter temperatures and handle higher loads — this raises performance but also allows for shared cooling infrastructure. The shared infrastructure can itself be improved by using new pure-copper 3D printing techniques, which allow more cooling to fit inside the housing. Using 3D printing means custom internal geometries so that the motor, gearbox, and power delivery can all be mounted in optimal positions to one another instead of bolted on where existing methods allow.

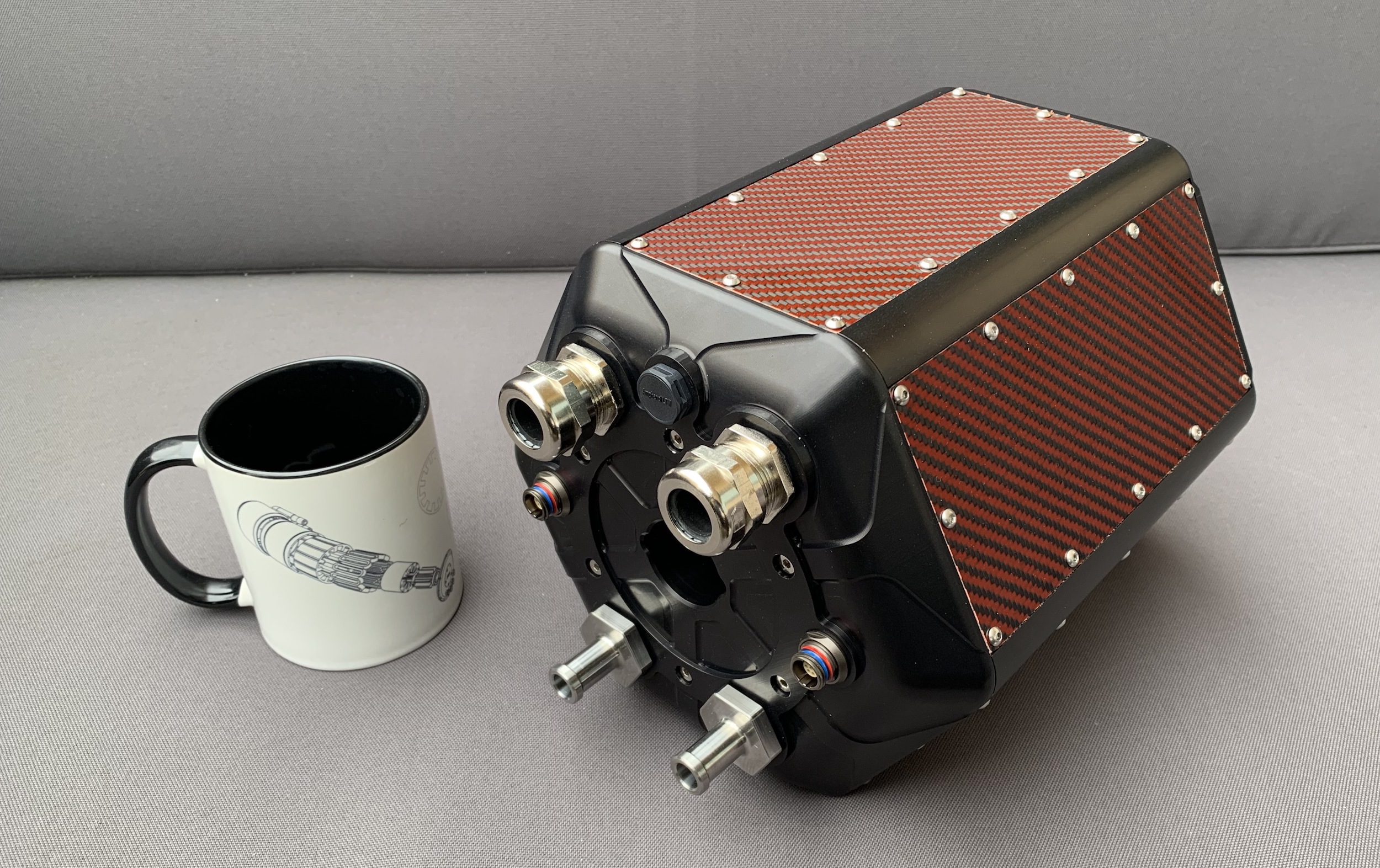

The result is an all-in-one motor, the HPDM-250, that’s smaller than a lot of the competition, yet produces far more power. The best production motors out there are around 3-4 kilowatt-hours per kilogram of continuous power. H3x’s prototype produces 13 — coincidentally, just above the theoretical efficiency that would enable mid-range passenger aircraft.

There is the risk that stacking cutting edge techniques like this makes the cost rise faster than the performance. Liben said that while it’s definitely more expensive in some ways, the smaller size and integrated design also lead to new savings in cost, time, or material.

“People think, ‘3D printing copper, that’s expensive!’ But when you compare it to the super high performance linings you’d need otherwise, and the different ways that you manufacture them, that can require a lot of manual steps and people involved… it can be a lot simpler printing something,” he explained. “It can be counterintuitive, but at least from my BOM [bill of materials] cost, when you’re selling something three times smaller than the other guy, even if it’s high performance materials, it’s actually not as expensive as you’d think. Based on the customers we’ve talked to so far, we think we’re in a good spot.”

Servicing a fully integrated motor is also fundamentally more complex than doing so for an off the shelf one, but Liben noted that they were careful to think about maintenance from the start — and also that, while it may be a little harder to service their motor than an ordinary electric one, it’s much, much simpler than servicing even the most reliable and well-known gas-powered motors.

Despite the huge gains H3x claims, the target market of passenger aircraft is hardly one that they, or anyone, can just jump into. Heavily regulated industries like air travel require years of work and technology proving to change a fastener style, let alone the method of propulsion.

So H3x is focusing on the numerous smaller, less regulated industries that could use vastly improved electric propulsion. Cargo drones, electric boats, and air taxis might still be rare sights on this planet, but a big bump to motor power and efficiency might be what helps tip them from niche (or vaporware) to mainstream. Certainly all three of those applications could benefit hugely from improved range or payload capacity.

Graduating to passenger flights isn’t a distant dream, exactly, suggested Liben: “We’re already on our way — this isn’t 20-years-out type stuff. In the last few years the timelines have shrunk drastically. You could have a full battery electric vehicle soon, but it isn’t going to cut it for longer flights.”

There’s still a role for motors like H3x’s in hybrid aircraft that use jet fuel, batteries, and perhaps even hydrogen fuel cells interchangeably. Like the switch to electric cars, it doesn’t happen all at once and it doesn’t need to for the purposes of their business. “That’s the great thing about motors,” Liben said. “They’re so ubiquitous.”

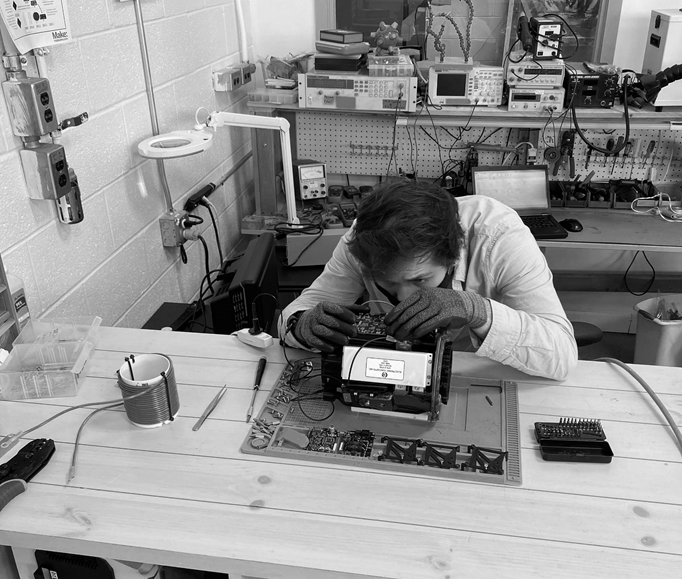

H3x declined to disclose any funding or partners, although it’s hard to believe that the team could have gotten as far as it has without some kind of significant capital and facilities — this sort of project outgrows the garage workbench pretty fast. But with Y Combinator’s demo day happening tomorrow, it seems likely that they’ll be receiving a lot of calls over the next few weeks, after which it may be reasonable to expect a seed round to come together.

If H3x’s prototypes perform as well in the wild as they do on the bench, they may very well enable a host of new electric transportation applications. We’ll be watching closely to see how the startup’s play affects the future of electric mobility.